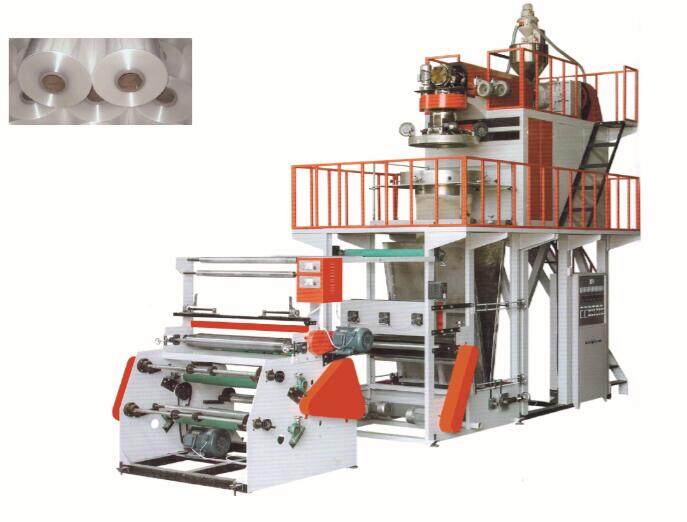

Our company specializes in the production of three-layer blown film machines that offer significant energy-saving benefits and enhanced flexibility in production applications, all at a reduced cost. Our ABC three-layer co-extrusion blown film machines feature three main motors that facilitate the extrusion process for each layer. This innovative design allows for a streamlined production line, leading to cost savings, reduced energy consumption, and overall efficiency.

The three-layer ABC co-extrusion blowing film machine is particularly advantageous as it is capable of producing HDPE, LLDPE, and LDPE films. By utilizing multi-layer co-extrusion technology, this machine enhances the physical toughness of the film produced. With a single main extruder supplying material for both the outer and inner layers, the need for additional extruders is minimized, resulting in energy savings and lower consumption rates.

In summary, our three-layer blown film machines are designed to optimize production processes, improve product quality, and achieve cost-effective operations, making them a valuable asset for businesses in the film manufacturing industry.

| Technical Variables |

|

|

|

|

| 型号 |

Mode |

3SJ-1100 |

SJX3-1350 |

SJX3-1700 |

| 螺杆直径 |

screw diameter |

φ55×2 φ60×1 |

φ60×2 φ65×1 |

φ65×2 φ70×1 |

| 螺杆长径比 |

screw ratio L/D |

28:1 |

28:1 |

28:1 |

| 螺杆转速 |

screw speed |

15-120r/min |

15-120r/min |

15-120r/min |

| 主电机功率 |

main motor power |

15kw×218.5kwx1 |

18.5kwx222kwx1 |

22kw×230kwx1 |

| 单挤出机产量 |

extrusion output(single |

80kg/h |

100kg/h |

140kg/h |

| 模口规格 |

ange of die-tip |

φ150 φ220 |

φ180 φ250 |

φ250 φ350 |

| 薄膜厚度单面 |

single layer thickness of film |

0.02-0.15mm |

0.02-0.15mm |

0.02-0.15mm |

| 薄膜最大折径 |

max layflat width of film |

1000mm |

1200mm |

1500mm |

| 电器总容量 |

nstallation capactity |

90kw |

105kw |

120kw |

| 外形尺寸 |

overall dimension |

6600×4100×5800 |

6800×4300×6000 |

7000×4800×7500 |

| 机器重量 |

weight of machin |

5.5T |

6.2T |

7.5T |

Optional Device:

1)Auto Loader

2)Air Compressor

3)Rotary Die Head

4)Double Side Winder(Back to back winder)

5)Up and Down

6)Embossing Cylinder

7)Air Shaft

8)Masterbatch Dosing device

9)Automatic Winder Changer

10) Corona treatment

※Correct specifications depend on the actual model. All specifications are subject to change without prior notice.

If you buy one container machines,we will pack machine with stretch film and loading container directly (FCL full container load).

If you only buy one machine,we will pack machine with wooden pack,and loading container with Less Than Container Load(LCL).

Our Main parts cooperator as following brand,but standard parts all made from China.

How To Find Polyethelene For Blown Film Extrusion.

Extrusion Film Extrusion use Polyethelene,such as

Low Density Polyethylene(LDPE),High Density Polyethylene(HDPE) and Linear Low Density Polyethylene(LLDPE),Polypropylene(PP).

Below are big brand material supplier in the world,they open office all over the world,you can check them in local market.

1.Sabic Saudi Basic Industries Corporation

2.ExxonMobil Chemical Company

3.Dow Chemical Company